The Apprentice: Dorcas Olawunmi Olayioye

Dorcas Olawunmi Olayioye was placed as a food safety and product development apprentice at Fastizers Foods and Confectionery Ltd in Nigeria.

As an enthusiastic food science (MSc) graduate with limited manufacturing experience, she found that the apprenticeship allowed her to apply her academic training in food safety, research and development, product formulation and optimization, market research, sensory testing, surveys, packaging development, and the use of Microsoft Office tools. She also gained a deeper understanding of the complex balance between profit-making and maintaining food quality and safety in a manufacturing environment.

During her apprenticeship, she was tasked with improving Fastizers’ hygiene culture. With strong support and clear guidance from management, she successfully led and facilitated the development of a facility-specific sanitation program while monitoring and training employees—efforts she carried out despite challenging economic factors.

She received immense support from PFS’ Program Director Vivian Maduekeh, who was always accessible and offered valuable learning opportunities. Vivian provided the technical resources Dorcas needed to succeed and served as a mentor, helping her navigate the balance between her passion for food safety and the economic realities of food manufacturing. Her line manager, Samuel Oparinde, also played a pivotal role by helping her build confidence in product development.

The year-long experience gave her a comprehensive foundation for navigating the food industry as a food scientist. Though intense, it offered her the chance to “fly,” demonstrating her theoretical knowledge and skills and leaving a sustainable impact on the company. In the years since, she has continued to build on the skills, knowledge, and relationships gained through the program—growth that has led to her current role as a sanitation supervisor at The Little Potato Company in Canada.

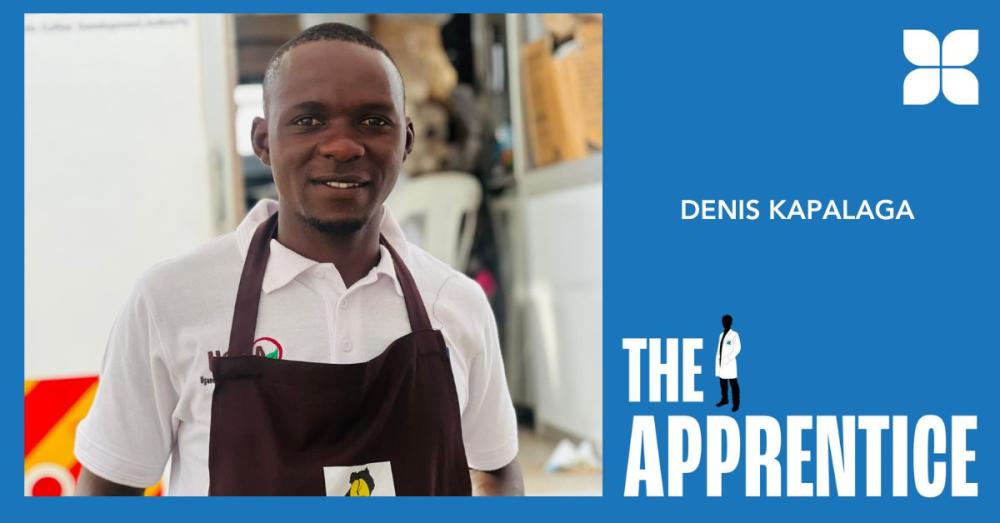

The Apprentice: Denis Kapalaga

During his apprenticeship with MADDO Dairies in Uganda, Denis Kapalaga served as a quality controller. There, he learned how to work in a professional environment and collaborate with diverse teams. He also learned how to effectively manage his time and quickly solve problems.

One project during his apprenticeship which stood out to him was a challenge with addressing lumps in yogurt production. He and his team improved the yogurt’s texture and consistency by resolving issues with mixing, ingredient quality, and temperature control during pasteurization. This experience reinforced to him the importance of paying attention to detail, research and teamwork within the food industry.

His supervisors were also of great help, offering regular feedback, hands-on training, and giving him opportunities that boosted his confidence and enabled him to take on more significant responsibilities.

With the lessons and skills from his apprenticeship as a foundation, Denis continues his career as a quality assurance officer at the Uganda Coffee Development Authority.

The Power of Virtual Training: Connecting the Globe with Industry-Specific Knowledge

In a world where knowledge is the backbone of progress, virtual training is becoming a transformative force. For PFS, that means delivering technical and industry-specific expertise across geographic, linguistic, and economic barriers, unlocking the vast potential in Africa’s food businesses. Two recent examples—the Rice Yield Calculation Webinar and the Occupational Health and Safety (OHS) Workshops for African Apprentices—highlight the significant role of virtual training in advancing technical training and workforce development globally at scale.

Reaching the Field: Rice Yield Webinar Goes Global

A recent webinar on calculating rice yield brought together 236 participants from 17 countries, with live interpretation in both English and French. Delivered by volunteers Asif Abbas, Bühler’s Managing Director for Asia Vietnam, and Dr. Griffiths Atungulu, Director of the University of Arkansas’ Rice Processing Program, the session provided valuable insights into optimizing rice production—a vital process needed for rice millers to improve their operations and product.

The feedback was overwhelmingly positive. Attendees noted the clarity of the presentation, practical approach, and its immediate relevance to their daily work. The two-hour training offered essential tools that can directly impact operational outcomes.

Creating Safer Workplaces: OHS Training for African Apprentices

Just days before the rice webinar, PFS hosted our annual apprentice workshop with three virtual OHS training sessions, attended by 90 current and former apprentices across six African countries.

The content covered a wide range of safety topics, from hazard identification to internal safety inspections, stress management, and strengthening safety culture through employee engagement. The training was interactive, practical, and tailored to real-world workplace scenarios.

Participants praised the sessions for their relevance:

"The facilitator was engaging and used real-life examples we could relate to."

"The interactive format allowed us to learn from each other."

"This was a wake-up call on the importance of engagement for improving safety practices."

The apprentices also expressed intentions to train peers, improve communication about OHS practices, and adopt better planning, and commit to the use of PPE.

Why Virtual Training Works

Though PFS has been providing virtual technical and business assistance for over 15 years, the COVID-19 pandemic was when it’s use and power was really recognized by the wider world. Even post-pandemic, virtual learning continues to grow: a 2023 report by Global Market Insights projects that the e-learning market will exceed $1 trillion by 2032.

The benefits of virtual training are clear, with internet access, learners from remote or underserved areas can access expert-led sessions—often in their own language. The reach and scalability is huge, with one well-designed session able to reach hundreds, and potentially thousands, of participants. The cost-effectiveness is also real. Though PFS’ engagements are very ‘high touch’ there are many opportunities to provide more generalized training to larger groups of professional such as the two we just offered.

For regions where in-person, expert-led training is logistically or financially challenging, virtual learning opens doors that were previously closed.

Looking Ahead

As these examples show, virtual training is not just a temporary solution—it’s a long-term strategy for closing global knowledge gaps and PFS has plans to use this tool more and more. The fact that we have so many highly-speciallzied, industry-leading experts in our pool of volunteers is a huge advantage to all of our clients, and the African food processing industry in general. For example, because we have just started our work with rice processers in West Africa we had only directly invited 60 people to the training. However, word of mouth spread and the opportunity was also shared on Linkedin. We had nearly 300 registrations, and for those that weren’t able to attend the video and course materials are still available to them. It shows that there is significant demand and the opportunity to access timely, relevant, and practical training has the power to drive real-world impact.

Thanks our dedicated volunteers and eager learners, we are seeing that transformation unfold—one webinar, one workshop, one food processor at a time.

The Apprentice: Marian Appiah

“I had always wanted to work in the non-profit and development space, so I was thrilled when I got the opportunity to work with PFS after graduating from the University of Ghana in 2018 with a BSc in Food Process Engineering. It was the right start to achieving my career goals.

I was placed with Eden Tree in Ghana as a quality control apprentice. While there, I supported the implementation of a Hazard Analysis Critical Control Points (HACCP) system. It was a challenging task for someone fresh out of school like me, but PFS supported me with several training courses in food safety and internal auditing that helped me to successfully go through it.

During my apprenticeship, I also gained technical skills in food safety management, HACCP training and food systems. I acquired leadership skills, internal and external communication skills and team building skills.

One of the best memories of my apprenticeship was when I met some PFS staff and volunteers from the United States in April 2019. I got the chance to interact with them, as well as apprentices from the previous cohorts. It felt like we were a big community, and it made me appreciate the growth of PFS.

Currently I am employed with Catholic Relief Services as a senior project officer where I oversee project implementation of large-scale food fortification objectives in West Africa by collaborating directly with national partners.”

Nigerian Client Upgrades Packaging with 'Kaizen' Mindset

Founded in 2014, Amel Susan is a Nigerian food company specializing in breakfast cereals, cocoa beverages, and baking products. As a valued PFS client since 2018, they have actively leveraged PFS services to enhance their operations.

One of their recent requests was for advice on procuring automated packaging lines for their icing sugar products. Having expanded their factory, Amel Susan needed expert guidance on selecting packaging lines that fit their new space. Though their primary request was for supplier recommendations, they also sought solutions for dust control, vibration mitigation, process flow optimization, and maximizing the efficiency of their grinding machines.

To support this project, PFS matched Amel Susan with Iluobe Osazemhen, a Bühler automation engineer. Iluobe brings extensive expertise, with a bachelor’s degree in electrical and electronics engineering from Nigeria, a master’s in automation and control engineering from Scotland, and an advanced diploma in industrial automation from Canada. After working with Bühler in Nigeria, he now serves as a customer service automation engineer in Canada, providing technical support to Bühler’s North American clients.

“I have gained diverse experience in problem-solving, workplace culture, and technical skills from the various countries I have lived in. Volunteering with PFS allows me to apply these skills to processors in need, aligning with PFS’ vision,” shared Iluobe.

Iluobe’s first step in the project was to understand Amel Susan’s current processes and long-term goals. By actively listening to and engaging with their engineering team, he helped streamline the selection process, ensuring the chosen solution aligned with their needs. Several factors were carefully considered throughout the process. This included the client’s budget; the equipment’s warranty; availability and cost of spare parts; technical support and maintenance feasibility; as well as scalability of the equipment and future upgrades. Through vendor research and local site visits by the Amel Susan team, they successfully identified and selected a packaging solution that met their needs. “With a ‘Kaizen’ (a Japanese word meaning continuous improvement) mindset, I always strive to leave systems better than I found them," said Iluobe. "This project demonstrated how process changes can significantly boost productivity and seeing the client’s satisfaction at the end—that feeling is priceless.”