General Mills’ European Volunteer Team Earns Global Volunteer Award

The General Mills Foundation is proud to announce a Global Volunteer Award has been given to a unique volunteer team that supported a Partners in Food Solutions (PFS) project to help Golden Bees Ltd. in Uganda.

Golden Bees provides a wide range of beekeeping products and services, such as packaging and honey processing (sourced from over 2,000 local beekeepers), tinctures, beeswax, bee equipment, beekeeping feasibility studies, and beekeeping training and consultancies.

“When PFS came to General Mills with a project to help their client, Golden Bees, improve their inventory management system, develop a quality management system and a mini lab, and improve their use of a computerized accounting system, our volunteers across the globe were quick to raise their hands and form a new way of teaming up for a volunteer project,” says Minn Wang, senior program manager at the General Mills Foundation.

What resulted was the pilot of a volunteer team made up entirely of General Mills Europe employees.

“Our aim with this effort was to build up a workplace culture of volunteerism and teamwork at General Mills in Europe, and to offer our PFS client a project team that had the potential to work together seamlessly, avoiding the challenges of time zone differences and in some cases, working together on project work from the same location,” said Frederic Olivier, a manufacturing and engineering director for General Mills, Europe and Australia (EUAU), based in Nyon, Switzerland.

The six-month project included the following General Mills volunteers:

Project Manager: Frederic Olivier (Nyon, Switzerland)

Supply Chain/Inventory Project: Michele Canepa (UK), Jonathan Barnett (UK)

Finance/Computerized Accounting System: Raffaele Virgilio (Nyon, Switzerland), Francois Rouet (Yoplait Plant in La Mans, France)

Quality/Quality Management System and Build-Up of Mini Lab: Carlota Gonzalo (San Adrian Plant in Spain)

“Each of these volunteers made themselves available to their project clients via WhatsApp for informal discussions and check-ins between their scheduled bi-weekly project calls, which helped to expedite project work and resulted in a satisfying experience for everyone involved,” says Frederic.

The Result: Today, Golden Bees has started to manage basic accountability with a new local software program. They have upgraded their quality lab and empowered the quality team with many of our team’s recommendations. And Golden Bees is operating by using an Excel inventory management tool built by General Mills.

In an email to Frederick, Brian Mugisha, general manager of Golden Bees Ltd. said, “We are grateful for the General Mills PFS team’s immense contribution to Golden Bees. There is no way we can pay you back, other than working towards improving Golden Bees to one day be a ‘General Mills of Uganda.’ Fredrick, thank you for captaining us through these six months. We really appreciate the entire team’s world class business acumen.”

As a result of earning a Global Volunteer Award, members of this General Mills volunteer team will each receive a certificate of merit, a magnetic medal, and they will collectively choose a qualifying nonprofit of their choice to make a $500 foundation grant to.

African Field Staff Visit European Volunteers

Simon Hailu, food processing specialist for the PFS Alliance Program in Ethiopia, says now that he's been to Switzerland, he finally knows how it feels to be the milk processed by his dairy clients in Ethiopia!

Why's that?

It's because he's never been quite that cold! At the end of 2018, PFS staff joined field staff from Ethiopia, Zambia, and Malawi on a visit to PFS corporate partners in Switzerland and the Netherlands. The team toured processing facilities at Bühler, DSM, Cargill and also General Mills joint venture Cereal Partners Worldwide. They had the opportunity to meet with current and prospective volunteers, and to share about their work supporting food processors in home countries. It was a wonderful opportunity for us to bring the field experience to life at our European partners, connect with our amazing volunteers, and help our field staff understand the capabilities of our partners and volunteers.

As a bonus, we got to enjoy the holiday season in Europe and our field staff had the chance to take a day trip to the Alps and see snow for the first time! The members of the team summed the trip up nicely - it was a chilly but enlightening experience!

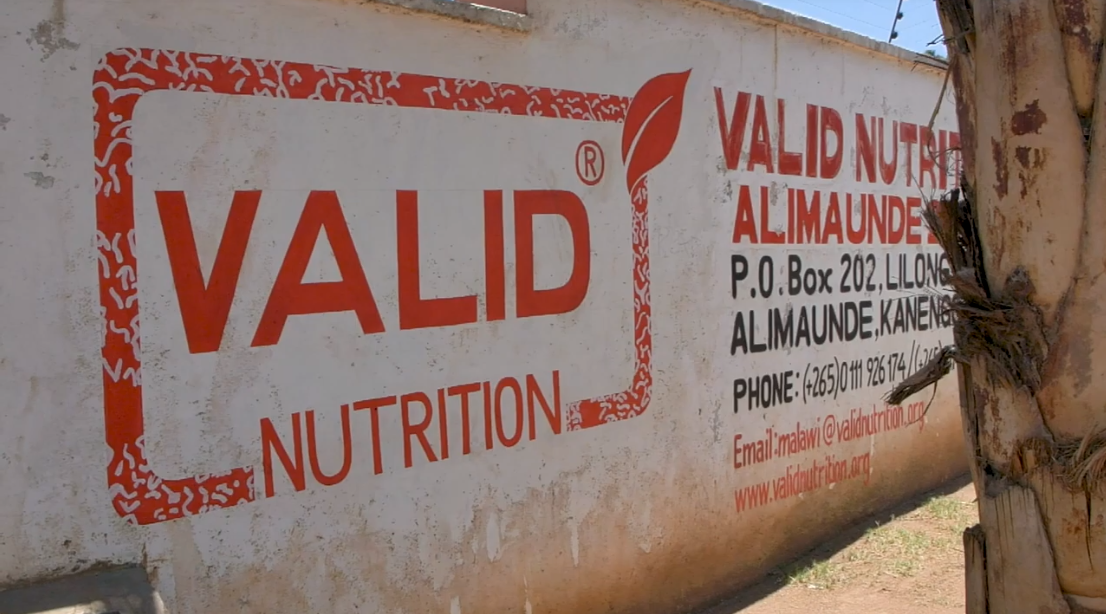

General Mills Video Features PFS Volunteer Work in Malawi

Taste of General Mills blog features our decade of work with our founding partner and the impact made in Africa and beyond. Read the story and watch the video HERE.

Taste of General Mills blog features our decade of work with our founding partner and the impact made in Africa and beyond. Read the story and watch the video HERE.

A Decade of Sharing

In 2008, when Indra Mehrotra was asked to bring a nutrition perspective to the early-stage PFS at General Mills, she was immediately hooked on the project.

“What a novel idea,” she remembers thinking. “I was totally enamored.” A decade later, and now working for another Partners in Food Solutions corporate partner, Cargill, she’s still captivated.

“I remember when we started, the idea of technology transfer was so exciting. But the enigma was how we were going to actually do it.” She says the entrepreneurial spirit was part of PFS right from the start, but challenges were presented by different time zones, geographies and the technology, which at the time wasn’t very good at bridging the distance between volunteers and clients. “Phone connections to remote parts of Africa were a real challenge. Once internet connections improved and we were able to better use email, it became a lot easier in so many ways.”

She says today the distance between clients and volunteers — in language, technology and culture — has been diminished considerably because communication is now easier and faster. Plus, the process and tools have been refined. “We’ve evolved

to a much more streamlined process where volunteers can get right to work helping our clients solve problems,” she says.

What keeps Indra engaged is the one thing that hasn’t changed in the past ten years — the focus on safe, nutritious, affordable food and economic development in Africa. “I feel it’s my professional responsibility to do this work,” she says.

Indra has a background in nutrition and now serves as Director of Scientific and Regulatory Affairs at Cargill. “Knowing the impact that nutrition has on health, it’s just something

I personally feel I need to do.” And today she says, “I think the focus is evolving from ‘food security’ to ‘nutrition security’ and that’s important.”

“I always believed that we could make an impact, and now we can see the results. I can see the changes made by our clients as a result of the knowledge volunteers have imparted,” she said, “Most of our client companies have benefited because they really just needed a boost.”

And it is that boost that she says is exactly what is needed on a continent that has the potential to not only feed itself, but help feed the rest of the world. “We have to unlock the potential of Africa. It must be brought into the system in order to solve global food insecurity.”